Applications in metalworking

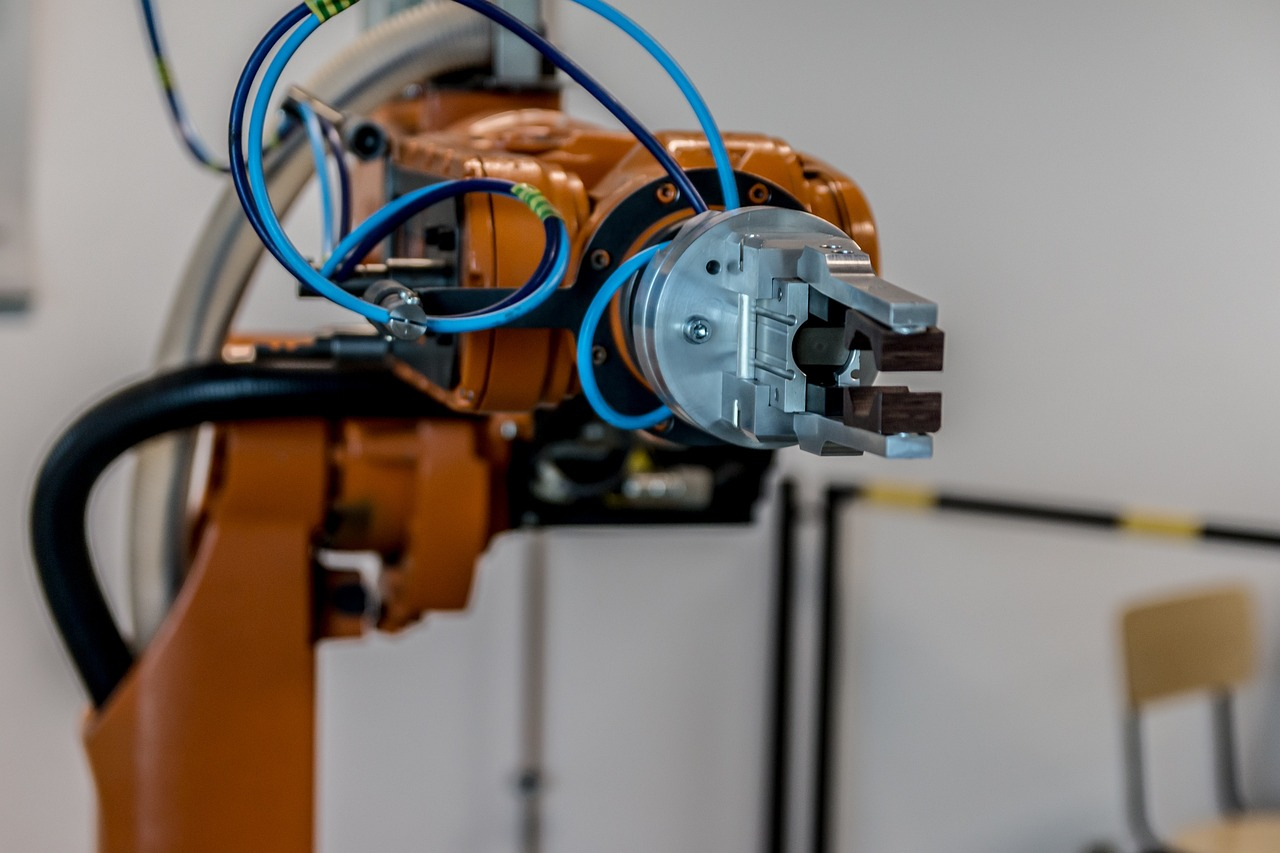

In precision metalworking, MABI Robotic Arm plays a crucial role due to its ability to perform tasks with exceptional accuracy. It is used in processes such as cutting, grinding, and welding, where even the smallest deviation can affect the quality of the final product. By automating these processes, robotic arms eliminate the risk of human error and ensure consistency in operations.

The use of the robotic arm in metalworking allows for increased production efficiency through faster work pace and minimized downtime. With programmable movements, the MABI Robotic Arm can precisely adjust its actions to meet the requirements of each task, which is especially beneficial for manufacturing complex components.

Automation of precision assembly

Another application of the MABI Robotic Arm is the automation of precision assembly in industries such as electronics or medical devices. Robotic arms can accurately position small components, which is crucial when assembling parts of microscopic size. Automating assembly using MABI arms enables higher levels of accuracy and reduces costs associated with rework.

Benefits for the automotive industry

In the automotive industry, where precision and production speed are essential, MABI Robotic Arm is widely used. It is employed for tasks such as welding body parts, painting, and assembling components, which accelerates the production process and improves quality. Through automation, car manufacturers can better adapt their production lines to changing market demands.

MABI Robotic Arm significantly contributes to the development of precision manufacturing, offering advanced solutions for the metalworking and automotive industries.